What is the lifespan of smart film?

The Lifespan of PDLC Film: Factors and Maintenance Tips

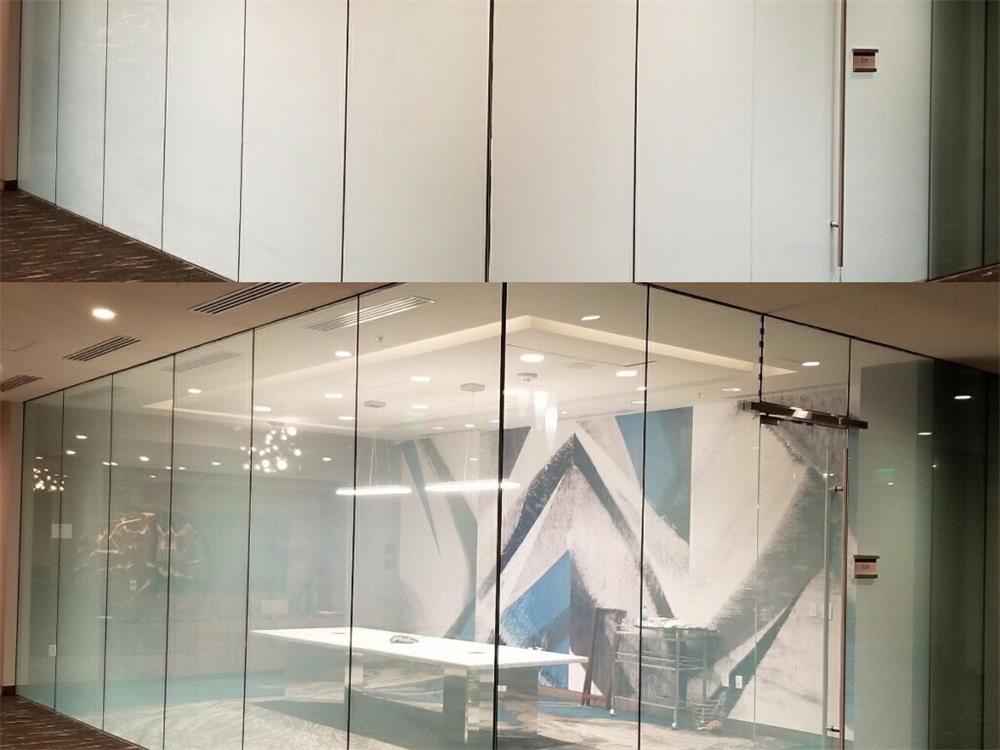

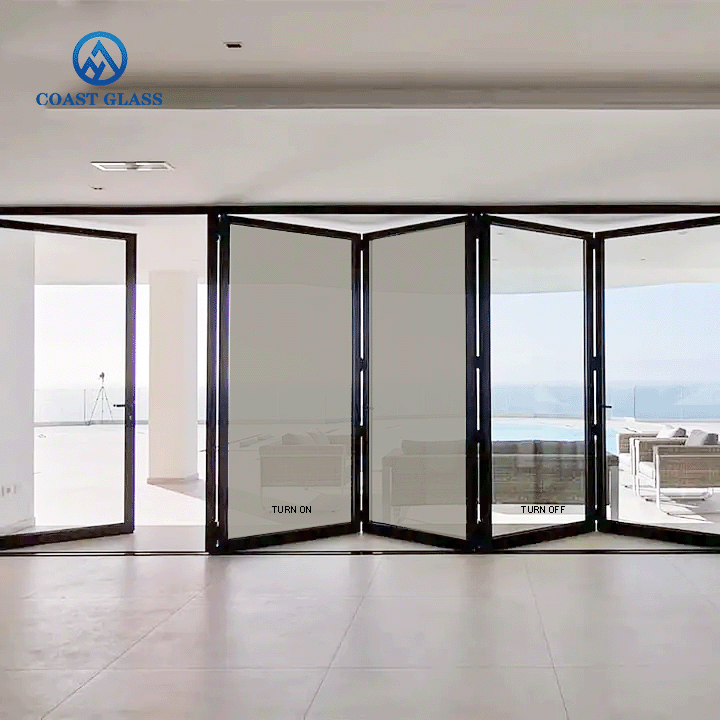

PDLC (Polymer Dispersed Liquid Crystal) film, also known as smart film, is an innovative material widely used in architecture, automotive, and home decoration. It can adjust its transparency through electric current, providing privacy and energy-saving benefits. However, many users are concerned about the lifespan of PDLC film. This article will explore the lifespan of PDLC film, the factors affecting it, and offer some maintenance tips to extend its lifespan.

Average Lifespan of PDLC Film

Generally, the lifespan of PDLC film ranges from 5 to 10 years. This lifespan depends on various factors, including material quality, usage environment, installation techniques, and daily maintenance. High-quality PDLC film, when properly installed and maintained, can reach or even exceed this lifespan range.

Key Factors Affecting the Lifespan of PDLC Film

-

Material Quality: High-quality PDLC films use better raw materials and manufacturing processes, offering greater durability and stability. These films can better resist wear and environmental impacts, thus extending their lifespan.

-

Usage Environment: The environment in which the PDLC film is used significantly affects its lifespan. In high temperatures, high humidity, or strong ultraviolet light environments, PDLC film may age more quickly. Therefore, when used under such conditions, it is recommended to choose PDLC films specifically designed for extreme environments.

-

Installation Techniques: Proper installation is crucial to ensuring the longevity of PDLC film. Improper installation can lead to bubbles, wrinkles, or poor adhesion, shortening its lifespan. It is advisable to choose a professional installation team for the job.

-

Usage Frequency: Frequent switching also impacts the lifespan of PDLC film. Although modern PDLC films are designed to be highly durable, long-term high-frequency switching can still cause wear on the electronic components.

Maintenance Tips to Extend the Lifespan of PDLC Film

-

Regular Cleaning: Keeping the PDLC film clean can prevent the accumulation of dust and dirt, avoiding surface scratches or contamination. Use a soft cloth and neutral cleaning agents for cleaning, and avoid strong acidic or alkaline cleaners.

-

Avoid Sharp Objects: During use, avoid contact between the PDLC film surface and sharp objects to prevent scratches or punctures.

-

Control the Usage Environment: In high-temperature or high-humidity environments, consider measures to reduce temperature or humidity to slow down the aging of the film.

-

Reasonable Usage: Avoid frequent and random switching of the PDLC film's transparency. Plan the usage frequency reasonably to reduce wear on the electronic components.

Conclusion

PDLC film is a high-tech product with a lifespan influenced by material quality, usage environment, installation techniques, and usage frequency. By choosing high-quality PDLC film products, ensuring proper installation, and performing regular maintenance, you can significantly extend its lifespan. We hope this article provides valuable information to help you better understand and maintain your PDLC film, ensuring it performs optimally in your life and work.

For more information about PDLC film, please visit our website. We are dedicated to providing you with high-quality PDLC film products and professional services to meet your various needs.